Edit on GitHub

Stepper Motors

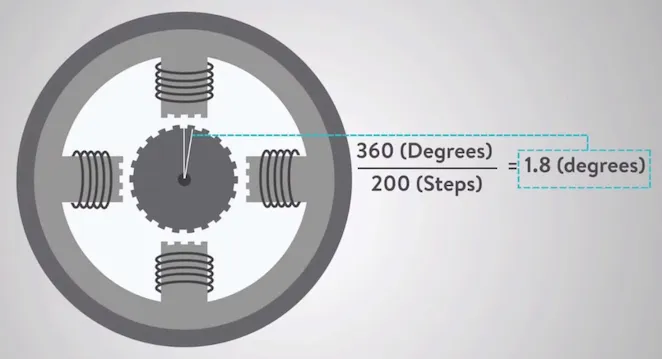

Steps per revolution

Number of steps the motor takes to complete one revolution

- 200 for 1.8°

- 400 for 0.9°

Microsteps

Number of microsteps your driver is configured to use per full step.

mm per revolution

For a leadscrew or ballscrew system

For a belt-driven system

Sample

Pulley: 2GT-20T

mm_per_revolution = 2mm × 20 = 40mm

Steps per mm

The formula to calculate steps_per_mm is:

Samples

TB6600 Microstepping Settings

The TB6600 stepper driver supports various microstepping settings controlled by three DIP switches (SW1, SW2, and SW3). Below is a table showing the switch configurations and the corresponding microstepping modes:

| Microstep Setting | SW1 | SW2 | SW3 | Steps per Revolution (for a 200-step motor) |

|---|---|---|---|---|

| Full Step (1) | OFF | OFF | OFF | 200 |

| Half Step (1/2) | ON | OFF | OFF | 400 |

| Quarter Step (1/4) | OFF | ON | OFF | 800 |

| Eighth Step (1/8) | ON | ON | OFF | 1600 |

| Sixteenth Step (1/16) | OFF | OFF | ON | 3200 |

| Thirty-second Step (1/32) | ON | OFF | ON | 6400 |